PORTFOLIO

home / PORTFOLIO

Completed Projects

Power Minerals (Wilton Site) - August 2019

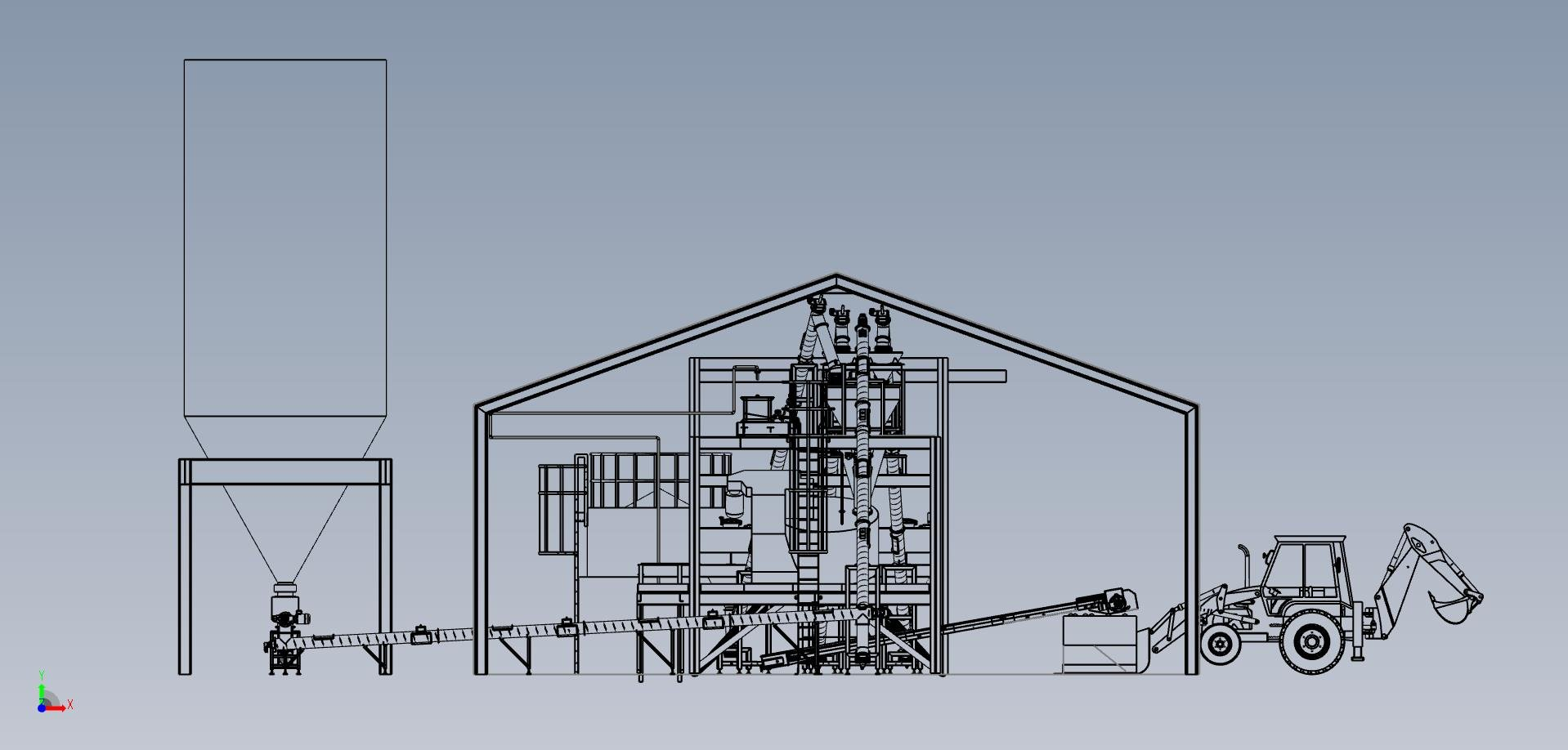

ADECA was awarded a project for the design of a control system with an innovative new process for recycling power industry by-products to create agri-products such as fertilisers. The plant was designed with maximum flexibility in mind. Allowing full traceability of infeed and output of materials.

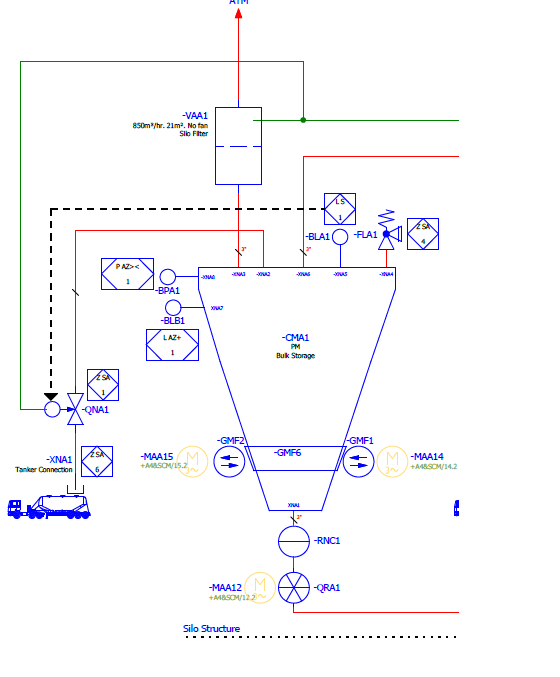

Concept Deisgn

The project started at the process design phase where the engineers produced a process flow diagram to establish the basic functionality of the plant. The preliminary design consisted of a P&ID URS and an electrical load schedule and allowed the site owners to plan the utility requirements and running costs of the plant.

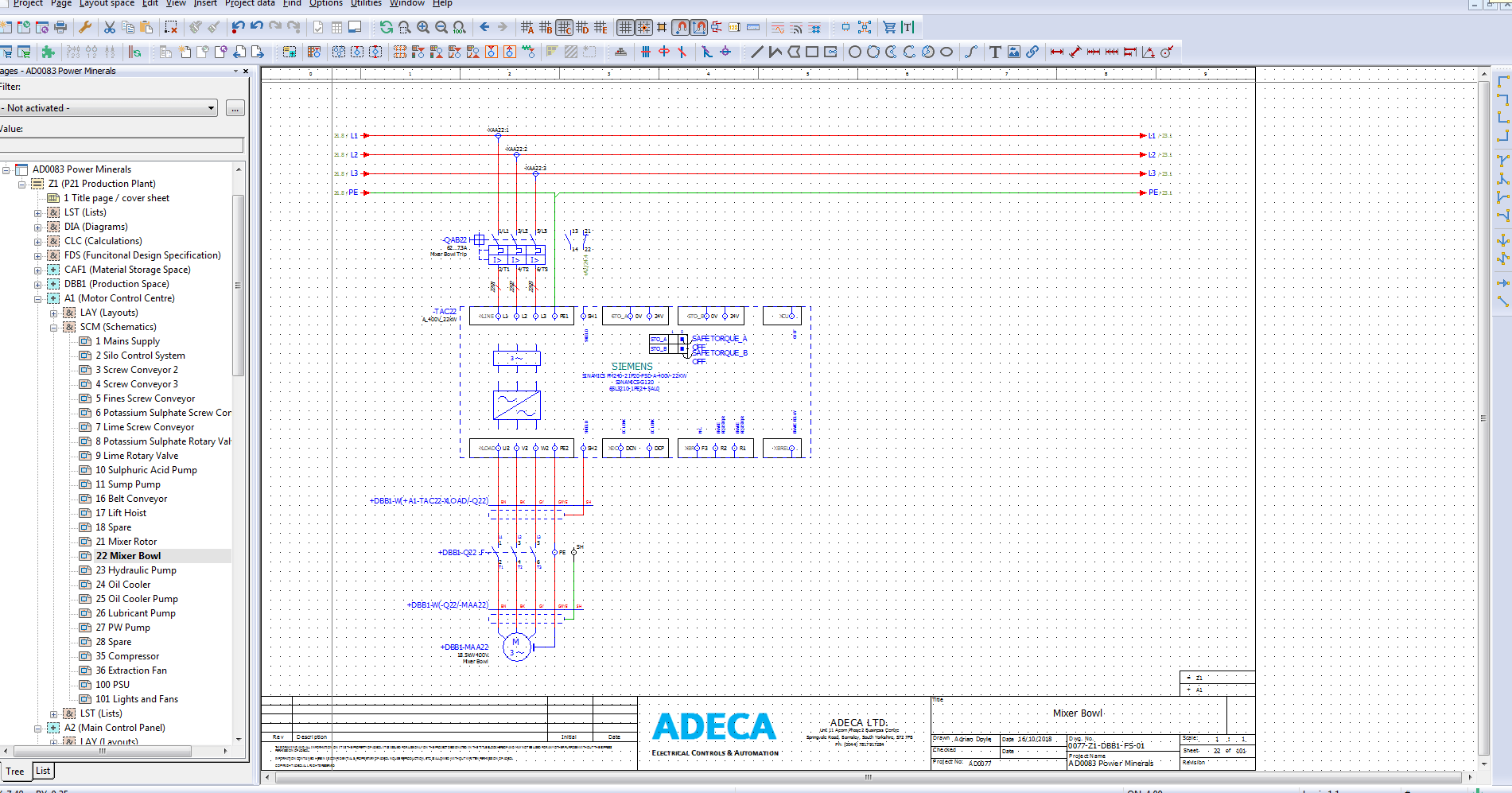

Detailed Engineering Design

Detailed engineering was completed with the following documents being issued for approval:

The software engineering was also completed at this stage using the PLC and RT simulators to verify the code and user interface prior to factory acceptance.

- Electrical loading and cable calculations

- Functional design specification

- Control panel schematics and GA

- Parts lists

- Bills of materials

- I/O schedule

- Factory acceptance schedule

- Installation plan

Once the detailed designs were approved the panels were then manufactured and tested. The following panels were built:.

- 1 x Motor control centre

- 1 x PLC and field wiring cubicle

- 3 x Remote I.O panels

- 1 x Remote HMI enclosure

Installation, commissioning and handover

The Installation

was completed by a team of subcontractors with minimal supervision from ADECA. The subcontractors used the documentation pack exported from EPLAN and Amtech to complete the installation phase.

- Cable Routing Plan

- Cable Schedule

- Cable Diagrams

- Termination Diagrams

The installation was inspected and a full inspection and test report was handed over.

Commissioning

commenced as soon as the installation was signed off.

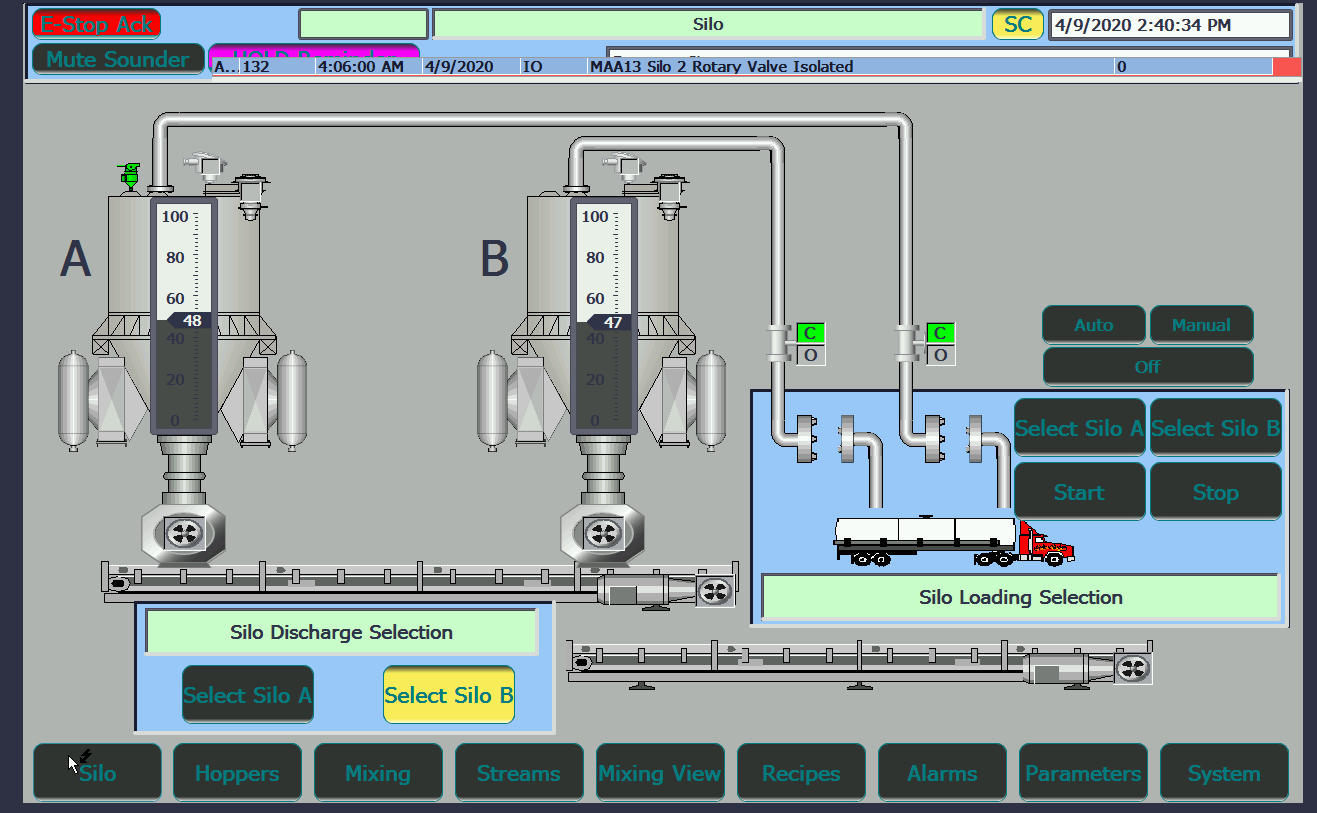

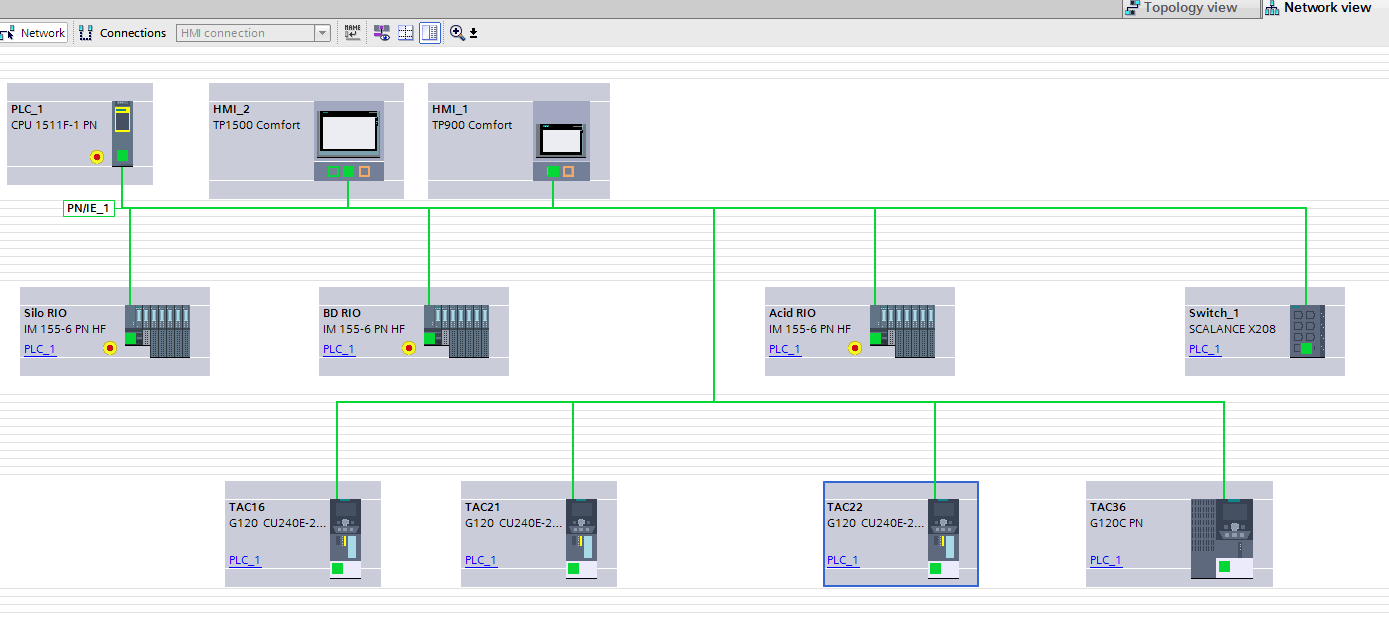

With nearly 400 points of I/O and 12 nodes the software team had their work cut out with only a short window to get it complete. However the Siemens TIA portal and Eplan P8 documentation pack helped make the process of commissioning much smoother.

The operators were trained and the as built documentation pack was handed over to close the project.

On completion of the project it was requested that a remote access point would be beneficial so an Ixon unit was installed with access via the Ixon cloud.

Data points were set up for so the higher level management could remotely monitor raw in feed material levels and monitor the plant condition.

This has also given the end user piece of mind knowing that an engineer can log in remotely via a secure network to help diagnose any issues.